Custom Order

£225.00 – £5,330.00

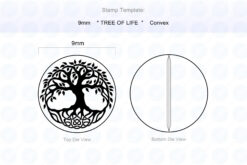

Please use this page to place your custom order for all TDP, RTP and ZP tablet press machines or fill in the form below to discuss your ideas.

All stamps come complete with a centre ring die(s) specific to your machine. Please use the drop down menu to select your machine model before purchasing. *Some new machines use the 37mm TDP 5 centre ring so please measure first to ensure correct fit.

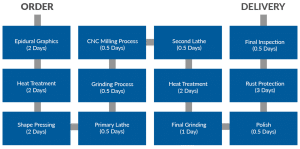

Please allow 25 – 35 working days for production depending on current manufacturing workload and design complexity.

Notify us with your order # and design once your order has been placed or simply fill in the form below if you cannot see your machine listed here or have a special request.

*Note: There is a minimum order quantity of 3 sets per design for unique custom TDP sets due to manufacturing limitations.